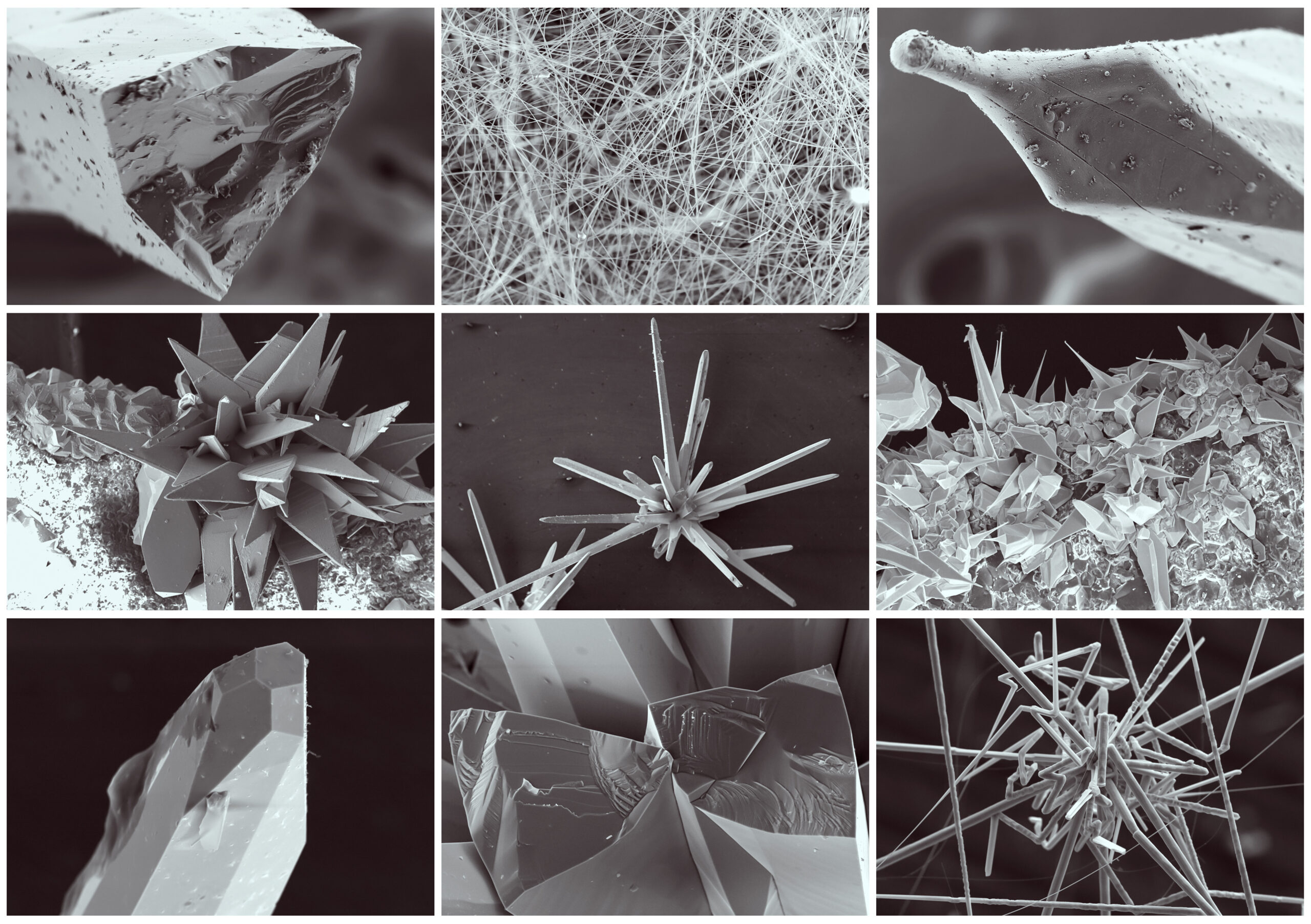

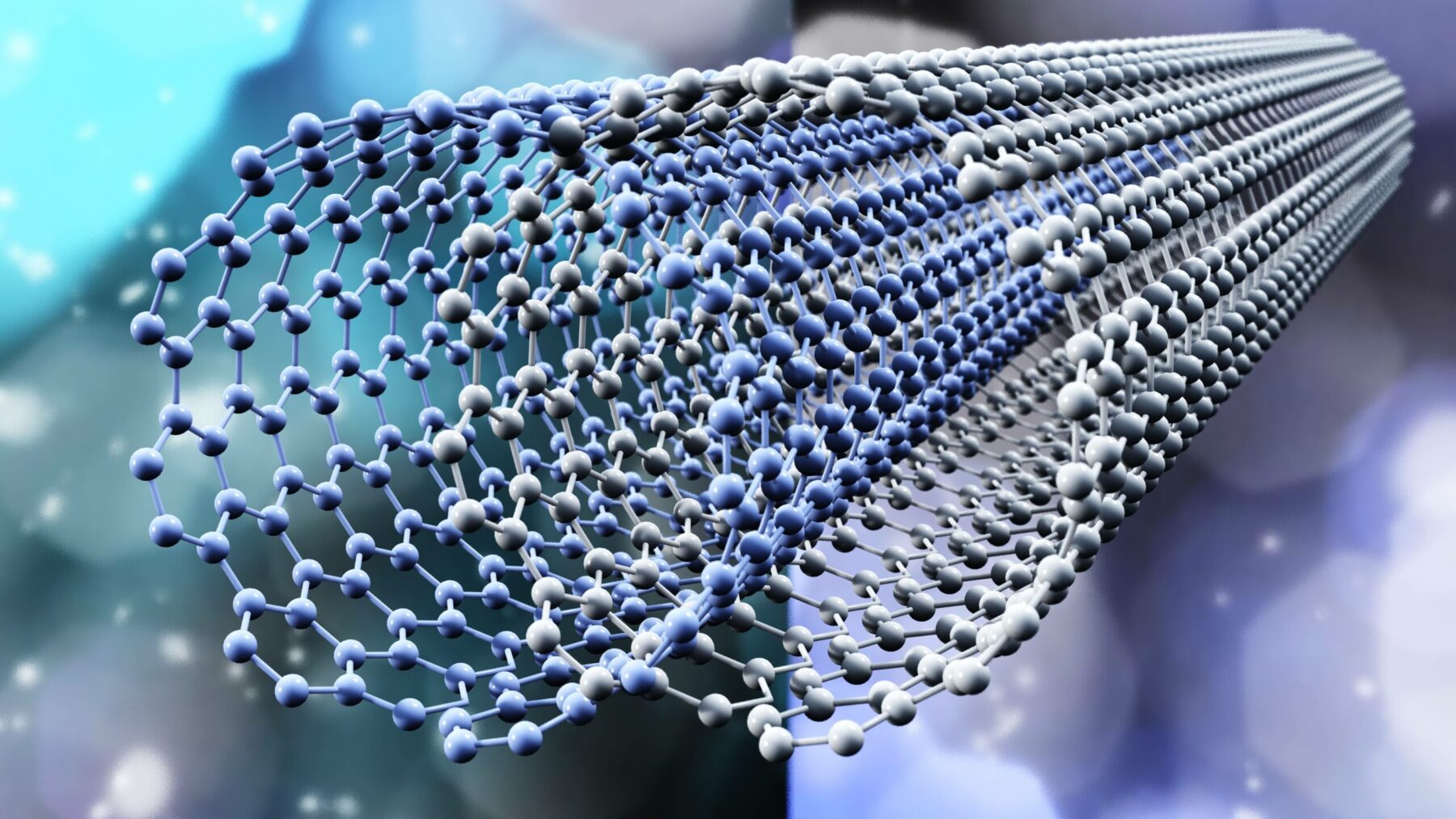

Nanomaterials Thin semiconductor layers

Nanomaterials

01Technika

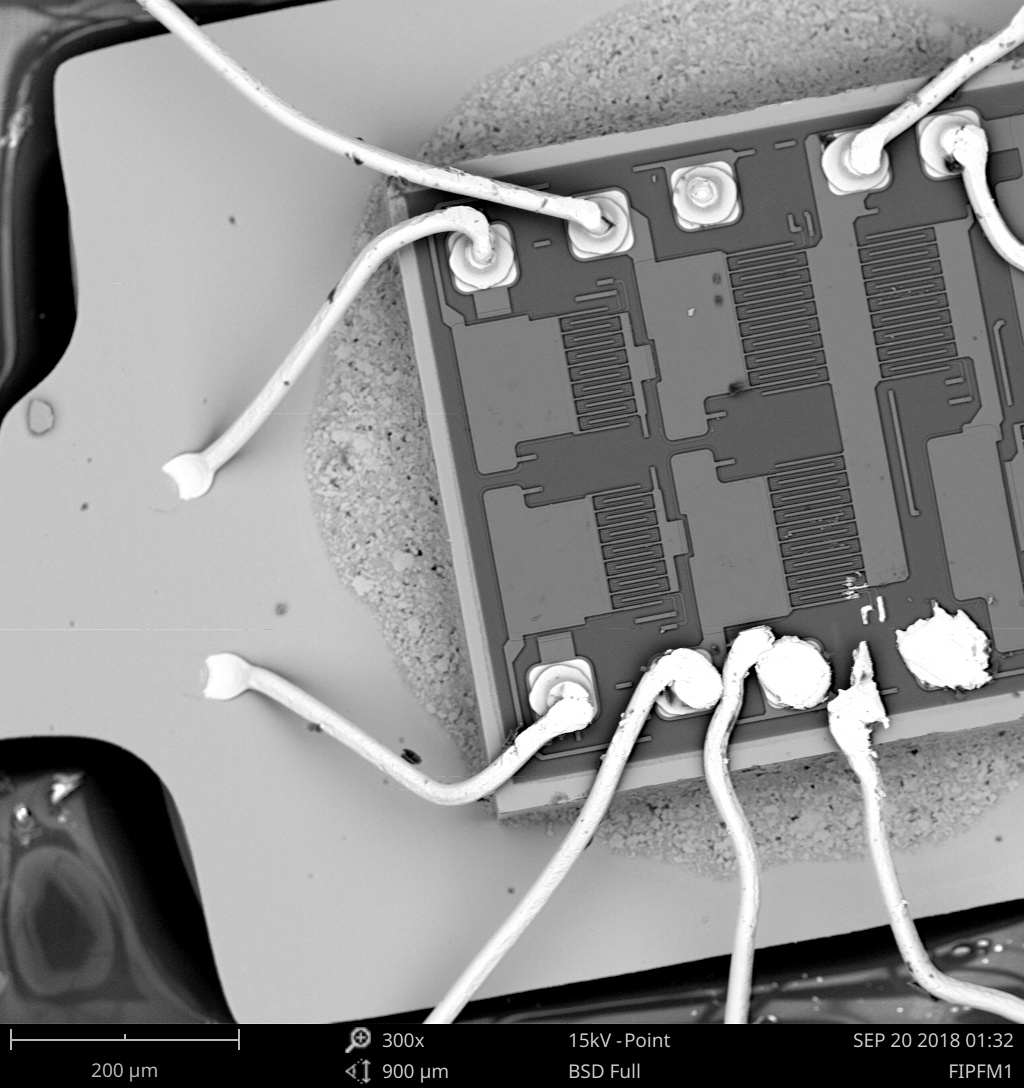

CBRTP has the instruments and scientific and engineering personnel acquired through nearly 10 years of experience in the delivery of research and industrial projects in many process engineering areas and scientific disciplines. CBRTP specialises in the design engineering and laboratory-scale and semi-industrial fabrication of semiconductors and dielectric materials, including composites deposited on any substrate. The type of technique to be applied varies with the type of substrate, requiring consultation and evaluation of materials before proceeding with the process.

02Deposition method

Magnetron sputtering (PVD)

- deposited materials: ZnO, TiO2, ITO, AZO, CuO, CuO2, NiO

- type of material and substrate geometry: flat surfaces; type of material – any, substrate dimensions – up to 200 mm in diameter

- additional excitation sources: resistive elements operating from 50°C to 450°C

- doping of oxide layers with other metals is possible

Atomic layer deposition (ALD)

- deposited materials: ZnO, TiO2, ITO, AZO, ZnS, SnS, CuS, CuO, CuO2

- nn any surface which is stable at 200°C, depending on the semiconductor type (200–400°C), with any surface development to a maximum within 200x200x600 mm3

- processed at 150–400°C

- superficial and volumetric doping of layers is possible

- production of structures with gradient changes in composition is possible

- layer crystallisation degree control is possible

03Applications

- photovoltaic cells

- sensors

- transparent electronics

- optical filters

- structures that modify the hardness and adhesion of all material types

- corrosion protection

- anti-reflective layers

- hydro- and oleophobic layers