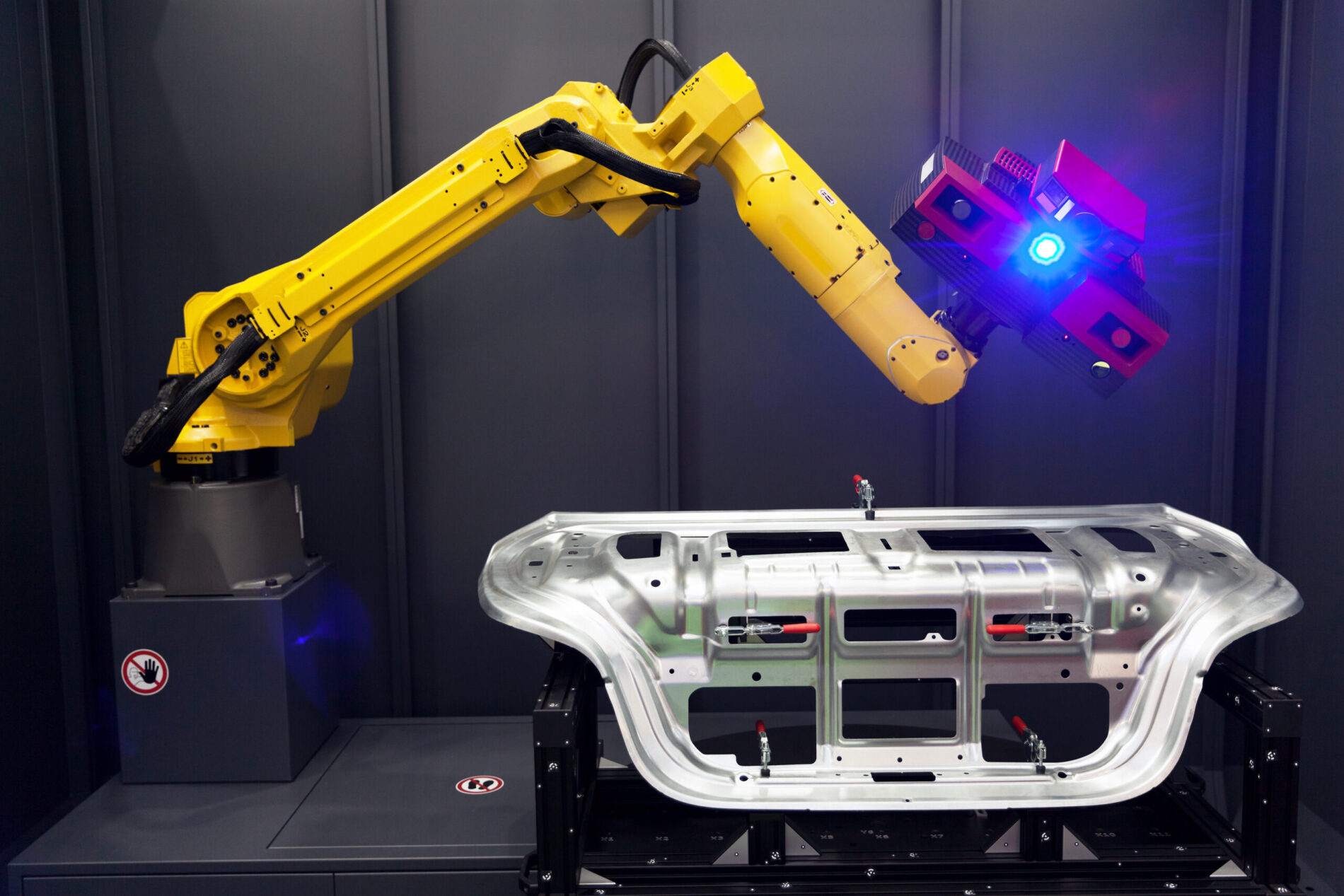

Engineering and Technology 3D measurement of part geometry

013D measurement of part geometry

The questions of 3D geometry measurement and 3D modelling have determined the trends now followed by the industry with the objective of improving the market strength of businesses. The digital revolution in instruments and software has made it possible to carry out high-quality verification of the workmanship of details, 3D builds, models, and the assembly of components and their positioning. CBRTP has the potential to meet current market demands and at the same time, thanks to the innovative work of our team, we set directions for further development of technology. The instruments we have meets all of the requirements and most stringent market-demand criteria for metrological inspection as per the prevailing standards. The CBRTP team has organically developed know-how in the form of a proprietary workpiece quality control system, and this solution enables building a database of master parts for real-time inspection on the production line, with an unprecedented scale of variability of part standards. The experience gained and the knowledge associated with the identification and interpretation of imaging outputs allow it to be appropriately applied in many manufacturing processes. CBRTP has an optical scanning instrument for the 3D measurement of parts with an accuracy down to 16 µm which is suitable for supporting customers in:

- verification of part manufacturing conformity in comparison to CAD models

- reverse engineering for the development of parts without any engineering documentation

- development of reference models

- digitising objects and creating point clouds or geometric meshes