Projekty Hydrophobic and barrier coatings

Projekty

Barrier and hydrophobic coatings for use in injection moulds

Data25/02/2022

Nazwa projektuNanomateriały

AutorCBRTP

01Project description

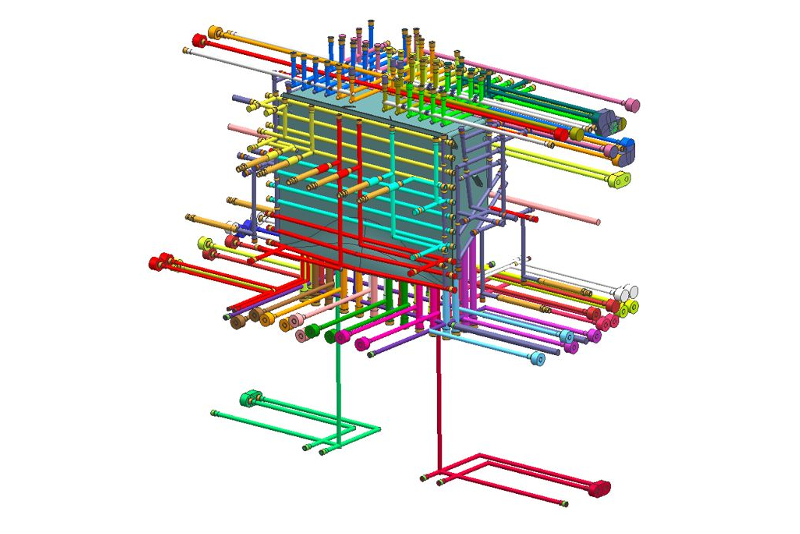

The aim of the project is to increase production efficiency by reducing or completely eliminating the maintenance cycles of injection moulds due to delaying the processes of contamination of the cooling channel system in injection moulds.

The project will be executed by a consortium composed of HANPLAST Sp. z o. o. and CBRTP SA. Part of the research work will be commissioned to two institutes of the Polish Academy of Sciences - the Institute of Catalysis and Surface Chemistry and the Institute of Fluid-Flow Machinery.

The stages of the project include the production of a demonstration installation, the acquisition of detailed data on the operating conditions of the cooling system, with particular emphasis on the cooling channels of the injection moulds, and the development of a model of the cooling system operation and the relationship of the pollution layer with the limitation of the flow and efficiency of heat exchange and the production process of details. The next step is to develop a technology for cleaning the cooling channels that allow obtaining the effect of automatic cleaning during the operation of the mould, as an alternative cleaning method to the current ones that require stopping the mould, and to develop technology for low-energy production of anti-corrosive and hydrophobic coatings that will protect the cooling channels against fouling. These technologies will all be integrated and verified under close-to-real conditions, and then demonstrated and optimised under the operational conditions of the HANPLAST manufacturing plant.

The results of the project will be innovative in the Polish and foreign markets. The innovation is process-oriented. The innovation is process-oriented.

The technology will be implemented in HANPLAST's business activities through its implementation as part of new investment in the reconstruction of the cooling agent distribution system throughout the plant. As a result, HANPLAST will increase the efficiency of the cooling system and thus the production efficiency. The indirect recipients of the results will be current and future HANPLAST customers, who will be able to increase the scale of annual orders.

The project is executed in connection with the agreement for co-financing of project No. POIR.01.01.01-00-0541/19-00 in the framework of Smart Growth Operational Program 2014-2020, Measure 1.1: R&D projects of enterprises, Sub-measure 1.1.1: Industrial research and development work carried out by enterprises.

The project will be executed by a consortium composed of HANPLAST Sp. z o. o. and CBRTP SA. Part of the research work will be commissioned to two institutes of the Polish Academy of Sciences - the Institute of Catalysis and Surface Chemistry and the Institute of Fluid-Flow Machinery.

The stages of the project include the production of a demonstration installation, the acquisition of detailed data on the operating conditions of the cooling system, with particular emphasis on the cooling channels of the injection moulds, and the development of a model of the cooling system operation and the relationship of the pollution layer with the limitation of the flow and efficiency of heat exchange and the production process of details. The next step is to develop a technology for cleaning the cooling channels that allow obtaining the effect of automatic cleaning during the operation of the mould, as an alternative cleaning method to the current ones that require stopping the mould, and to develop technology for low-energy production of anti-corrosive and hydrophobic coatings that will protect the cooling channels against fouling. These technologies will all be integrated and verified under close-to-real conditions, and then demonstrated and optimised under the operational conditions of the HANPLAST manufacturing plant.

The results of the project will be innovative in the Polish and foreign markets. The innovation is process-oriented. The innovation is process-oriented.

The technology will be implemented in HANPLAST's business activities through its implementation as part of new investment in the reconstruction of the cooling agent distribution system throughout the plant. As a result, HANPLAST will increase the efficiency of the cooling system and thus the production efficiency. The indirect recipients of the results will be current and future HANPLAST customers, who will be able to increase the scale of annual orders.

The project is executed in connection with the agreement for co-financing of project No. POIR.01.01.01-00-0541/19-00 in the framework of Smart Growth Operational Program 2014-2020, Measure 1.1: R&D projects of enterprises, Sub-measure 1.1.1: Industrial research and development work carried out by enterprises.

02Members of the scientific and industrial consortium

- Hanplast Sp. z o.o.

- Centrum Badań i Rozwoju Technologii dla Przemysłu S.A.

- Centrum Badań i Rozwoju Technologii dla Przemysłu S.A.

03Project data

Execution period: 01.01.2020 – 31.12.2022

Total eligible project cost: PLN 27 404 136.50

Industrial research: PLN 25 428 797.11

R&D: PLN 1 975 339.39

Amount of co-financing: PLN 19 775 503.86

Industrial research: PLN 18 985 368.11

R&D: PLN 790 135.75

Own contribution: PLN 7 628 632.64

Total eligible project cost: PLN 27 404 136.50

Industrial research: PLN 25 428 797.11

R&D: PLN 1 975 339.39

Amount of co-financing: PLN 19 775 503.86

Industrial research: PLN 18 985 368.11

R&D: PLN 790 135.75

Own contribution: PLN 7 628 632.64